Push-bar Type Tray Sealer with vacuum gas injection packing is ideal for medium to larger production runs of pre-made trays for seal only, vacuum & gas/modified atmosphere(MAP): vacuum extraction of all the air inside the tray, followed by the injection of the desired gas mixture or nitrogen. And vacuum skin(VSP): the packaging method consists in the vacuum extraction of all the air inside the tray. The film is then sealed inside the tray and along its edges. Drawn by the vacuum toward the product, the film fits around it like a second skin.

It’s suitable for packing powdery and grain products (such as beans, coffee, tea leaves, herbs and slit products...etc.) Fresh meat, seafood, pickled vegetables, agricultural products, herbs, bean paste and prepared foods ...etc

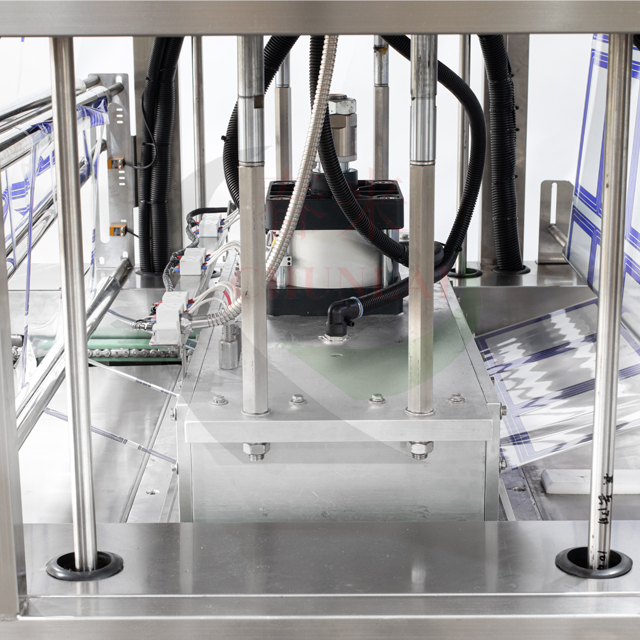

Trays put manually or empty trays are loaded by a tray denester on the infeed line and conveyed up to the sealing station. The sealing operation consists in welding a thermoplastic film on the edges of the trays, the operation being performed in a vacuum or in a neutral gas atmosphere. Before any sealing operation, a new length of film is unwound, positioned over the trays, welded on the edge of the trays and excess film wound again on a scrap roll.

Trays are displaced over the entire length of the machine by a transport system provided with a series of transverse push bars which are equidistantly mounted between two lateral driving chains.

vacuum gas packing sealing

Model | TF-2 | TF-4 | TF-6 |

Production capacity | 2 lanes | 4 lanes | 6 lanes |

Voltage | Single phase 220V, 3 phase 220V 3 phase 380V/400V/415V 50Hz/60Hz | ||

Power | 4KW | 5Kw | 6 Kw

|

Air consumption | 0.8 mз/min | 0.8 mз/min | 1 mз/min |

Dimension | 2400×700×1650 mm | 2400×850×1700 mm | 3000×900×1700mm |

Weight | 600Kg | 700Kg | 1000Kg |

Machine Frame: Stainless Steel

Bottom Molds: Aluminum Alloy

PLC: Mitsubishi

Cylinder: AirTac

Solenoid valve: Mindmand

Switch: IDEC

Servo driving

vacuum gas flushing

vacuum skin

only sealing